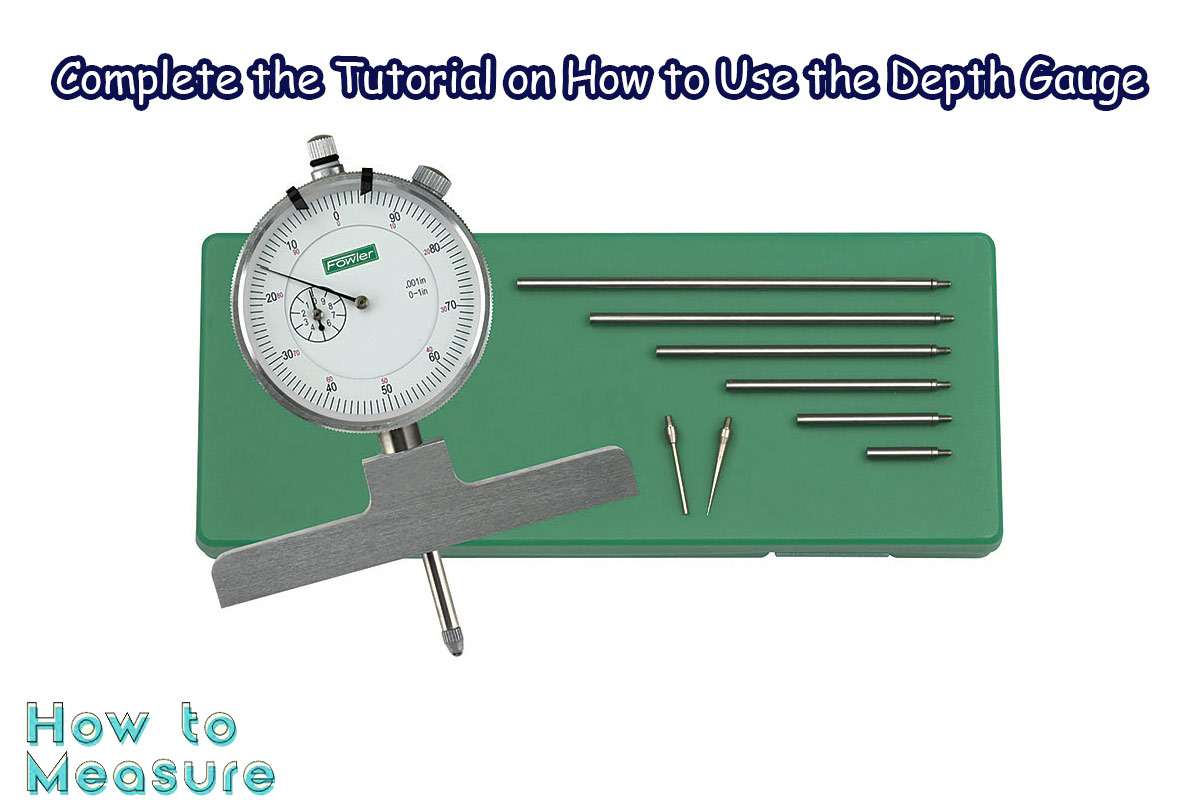

Depth gauges are essential for measuring the depth of a hole, groove, or another surface. They are used in various industries, from automotive and aerospace to woodworking and manufacturing. Knowing how to use a depth gauge properly is critical to achieving accurate measurements. This complete tutorial will provide a comprehensive overview of depth gauges, from essential functions to troubleshooting and maintenance. We will also provide tips and tricks, usage examples, and alternative tools to consider. With this guide, you can confidently use a depth gauge to measure with precision.

A depth gauge is a tool used to measure the depth of a hole, groove, or other recess. It is a versatile tool that can be used for various applications, such as measuring the depth of a hole in a wall, the depth of a groove in a piece of wood, or the depth of a recess in a metal part. In this complete tutorial on how to use a depth gauge, we will cover the overview of a depth gauge, its essential functions, how to measure with it, troubleshooting tips, safety precautions, maintenance, tips and tricks, examples of use, alternatives, and resources for further learning.

Overview of Depth Gauge

A depth gauge is a tool used to measure the depth of a hole, groove, or other recess. It is a versatile tool that can be used for various applications, such as measuring the depth of a hole in a wall, the depth of a groove in a piece of wood, or the depth of a recess in a metal part. The depth gauge typically consists of a handle, a rod, and a measuring head. The handle holds the depth gauge, and the rod extends the measuring head into the hole or recess. The measuring head is typically a small metal plate with a scale on it, which measures the depth of the hole or recess.

Essential Functions of Depth Gauge

Depth gauges measure the depth of a hole, groove, or recess. They are measuring tools that can accurately measure the depth of a hole or other object. Depth gauges come in various shapes and sizes and can be used for various purposes. The essential functions of a depth gauge include measuring the depth of a hole, groove, or recess and determining the exact depth of a surface.

Depth gauges are typically made of metal or plastic and have an adjustable measuring arm. The arm can be adjusted to measure the depth of a hole or other object. The arm can also be adjusted to measure the depth of a groove or recess. The measuring arm is usually connected to a dial or digital display that shows the depth measurement.

Depth gauges are typically used to measure the depth of a hole, groove, or recess in various materials, including wood, metal, plastic, and stone. They can also measure the depth of a surface, such as a countertop or a floor. Depth gauges are also used to measure the depth of a hole in a wall or other structure.

Depth gauges are an essential tool for any tradesperson or DIY enthusiast. They are used to accurately measure the depth of a hole, groove, or recess and can be used to measure the depth of a surface. With the correct depth gauge, you can ensure that your projects are accurate and precise.

Measuring With Depth Gauge

A depth gauge is a simple and accurate way to measure the depth of a hole, groove, or other recess. Understanding the basics of using a depth gauge before attempting to measure with one is essential. This tutorial will cover the basics of measuring with a depth gauge, including how to read the measurements, safety precautions, and tips and tricks for accurate measurements.

When measuring with a depth gauge, the first step is to select the correct size for the job. Depth gauges come in a variety of sizes, from small to large. Selecting the correct size for the job is essential to ensure accurate measurements. Once the correct size has been selected, the depth gauge can be placed into the hole, groove, or recess to be measured.

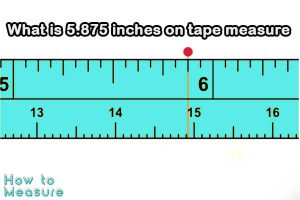

When measuring with a depth gauge, it is essential to ensure that the gauge is placed firmly against the bottom of the hole, groove, or recess. This will ensure that the measurements are accurate. Once the depth gauge is in place, the measurements can be read. Depth gauges are typically marked with increments of 1/64th of an inch. To read the measurements, count the number of increments on the depth gauge.

Safety precautions should be taken when measuring with a depth gauge. It is essential to wear safety glasses to protect the eyes from debris and dust. Additionally, it is essential to use caution when handling the depth gauge, as it can be sharp and cause injury.

When measuring with a depth gauge, it is essential to take multiple measurements to ensure accuracy. Taking multiple measurements will help ensure the measurements are accurate and consistent. Additionally, it is essential to take measurements from different angles to ensure accuracy.

Finally, keeping the depth gauge clean and free of debris is essential. This will help to ensure accurate measurements and prevent damage to the depth gauge.

In conclusion, measuring with a depth gauge is a simple and accurate way to measure the depth of a hole, groove, or other recess. Understanding the basics of using a depth gauge before attempting to measure with one is essential. This tutorial has covered the basics of measuring with a depth gauge, including how to read the measurements, safety precautions, and tips and tricks for accurate measurements.

Troubleshooting Depth Gauge

Depth gauges are handy tools for measuring the depth of a hole or cavity, but they can sometimes malfunction or give inaccurate readings. Fortunately, you can take a few simple steps to troubleshoot and resolve any issues you may have with your depth gauge.

The first step is to check the battery. If the battery is low, it can cause the depth gauge to give inaccurate readings. Make sure the battery is fully charged and replace it if necessary.

Next, check the accuracy of the depth gauge by comparing it to a known measurement. If the depth gauge is not giving accurate readings, it may need to be calibrated. This can be done by adjusting the zero point of the depth gauge.

If the depth gauge still needs to give accurate readings, it may be due to dirt or debris accumulated on the surface of the depth gauge. Use a soft cloth to clean the surface of the depth gauge, and then try again.

Finally, if the depth gauge is still not giving accurate readings, it may be due to a damaged or faulty part. Check the depth gauge for any visible signs of damage and replace any damaged parts as necessary.

Following these simple steps, you can quickly troubleshoot and resolve any issues with your depth gauge. With proper maintenance and care, your depth gauge should provide accurate and reliable readings for years.

Safety Precautions When Using Depth Gauge

- Always wear safety glasses when using a depth gauge.

- Keep your hands away from the moving parts of the depth gauge.

- Make sure the depth gauge is securely attached to the workpiece before beginning any measurements.

- Do not use a depth gauge on any material that is too hard or soft.

- Be sure to use the correct size and type of depth gauge for the job.

- Make sure the depth gauge is correctly calibrated before use.

- Make sure the depth gauge is clean and debris-free before use.

- Never use a depth gauge to measure depths greater than its capacity.

- Never use a depth gauge to measure too shallow depths.

- Always disconnect the power source before adjusting the depth gauge.

Maintenance of Depth Gauge

Proper depth gauge maintenance is essential to ensure accurate measurements and a long lifespan. Maintaining a depth gauge is vital to keep it clean and dry. After each use, wipe down the gauge with a clean, dry cloth. This will help prevent corrosion and other damage to the gauge. Additionally, it is essential to store the depth gauge in a safe place, away from moisture and extreme temperatures. It is also essential to regularly check the calibration of the depth gauge and adjust it if necessary. If the depth gauge is not functioning correctly, it is best to have it serviced by a professional.

Tips and Tricks for Using Depth Gauge

- Make sure the surface you are measuring is level. A level surface will ensure accurate measurements.

- Clean the surface before taking a measurement. This will ensure that any debris or dust does not interfere with the accuracy of the reading.

- Use a soft cloth to clean the depth gauge. This will help to prevent scratches or other damage to the tool.

- Take multiple readings to ensure accuracy. Taking multiple readings will help to ensure that the measurements are accurate.

- Use a magnifying glass to better view the measurements. This will help to ensure that the readings are accurate.

- Use a ruler to measure smaller objects. This will help to ensure that the measurements are accurate.

- Use a depth gauge in conjunction with other measuring tools. This will help to ensure that the measurements are accurate.

Examples of Using Depth Gauge

Depth gauges are versatile tools that can be used in various applications. Here are some examples of how to use a depth gauge:

- Checking the depth of a hole or recess: Depth gauges can be used to measure the depth of a hole or recess in various materials, such as wood, metal, and plastic.

- Measuring the depth of a groove or channel: Depth gauges can be used to measure the depth of a groove or channel in various materials, such as wood, metal, and plastic.

- Checking the depth of a threaded hole: Depth gauges can be used to measure the depth of a threaded hole in various materials, such as wood, metal, and plastic.

- Measuring the depth of a blind hole: Depth gauges can be used to measure the depth of a blind hole in various materials, such as wood, metal, and plastic.

- Checking the depth of a slot or keyway: Depth gauges can be used to measure the depth of a slot or keyway in various materials, such as wood, metal, and plastic.

- Measuring the depth of a recess or counterbore: Depth gauges can be used to measure the depth of a recess or counterbore in various materials, such as wood, metal, and plastic.

Checking the depth of a bearing race: Depth gauges can be used to measure the depth of a bearing race in various materials, such as wood, metal, and plastic.

Measuring the depth of a bore: Depth gauges can be used to measure the depth of a bore in various materials, such as wood, metal, and plastic. A depth gauge is a great way to measure various materials’ depth accurately. By following the instructions in this Complete Tutorial on How to Use a Depth Gauge, you can ensure that you use the tool correctly and safely.

Alternatives to Depth Gauge

While a depth gauge is a handy tool for measuring an object’s depth, several alternatives can be used. These include callipers, micrometres, and digital depth gauges. Callipers are used to measure the distance between two points, while micrometres are used to measure the thickness of an object. Digital depth gauges are a more accurate option and can measure depths up to 0.01mm. They are also able to measure depths in multiple directions. Other alternatives include optical comparators, dial indicators, and optical depth gauges.

Resources for Further Learning on Depth Gauge

Many resources are available for those looking to further their knowledge of depth gauges. Here are some of the best:

- Books: Reading books on the subject is a great way to learn more about depth gauges. Popular titles include “The Complete Guide to Depth Gauges” by John E. Walker and “Depth Gauge Handbook” by George L. Huxley.

- Online Tutorials: Many online tutorials are available for those looking to learn more about depth gauges. Popular tutorials include “How to Use a Depth Gauge” by Maker’s Tool Works and “Depth Gauge Basics” by Machinist’s Workshop.

- Videos: YouTube is an excellent resource for learning depth gauges. Popular videos include “Depth Gauge Tutorial” by Machinist’s Workshop and “How to Use a Depth Gauge” by Maker’s Tool Works.

- Forums: Forums are a great way to ask questions and get answers from experienced users. Popular forums include the Machinist’s Workshop Forum and the Maker’s Tool Works Forum.

- Manufacturers: Manufacturers of depth gauges often have detailed information about their products on their websites. Popular manufacturers include Mitutoyo, Starrett, and Fowler.

- Trade Shows: Trade shows are a great way to learn more about depth gauges from experts. Popular trade shows include the International Manufacturing Technology Show and the National Manufacturing Week.

Final Thoughts

In conclusion, using a depth gauge can seem intimidating, but with a few simple steps, it can be a valuable tool for measuring depths, distances, and levels. The first step is to ensure the gauge is appropriately set up and calibrated, with the appropriate contact point selected for the measured surface. Once the gauge is set up, it’s essential to ensure it is level and stable and to take multiple measurements to ensure accuracy and consistency. When taking measurements, it’s crucial to avoid applying too much pressure, which can distort the results and record measurements carefully and accurately. Additionally, it’s essential to properly care for and maintain the depth gauge to ensure its longevity and accuracy. With these simple steps in mind, anyone can use a depth gauge confidently and effectively for various applications, from woodworking and metalworking to mechanical engineering and construction.