Accurately measuring hydraulic hoses is essential for ensuring they work correctly and efficiently. It is important to know the length, diameter, internal pressure, temperature, wall thickness, bend radius, flow rate, burst pressure, and hose resistance. This article will discuss the different methods for measuring each parameter and provide helpful tips for getting the most accurate measurements. In the essay we in How to measure will talk more about this topic.

Types of Hydraulic Hose Measurement

Measuring hydraulic hoses is an integral part of any hydraulic system. Several measurements can be taken to ensure the hose is functioning correctly. The most common types of measurements include length, diameter, internal pressure, temperature, wall thickness, bend radius, flow rate, burst pressure, and resistance. Knowing how to measure each of these parameters is essential for ensuring the proper operation of the hydraulic system.

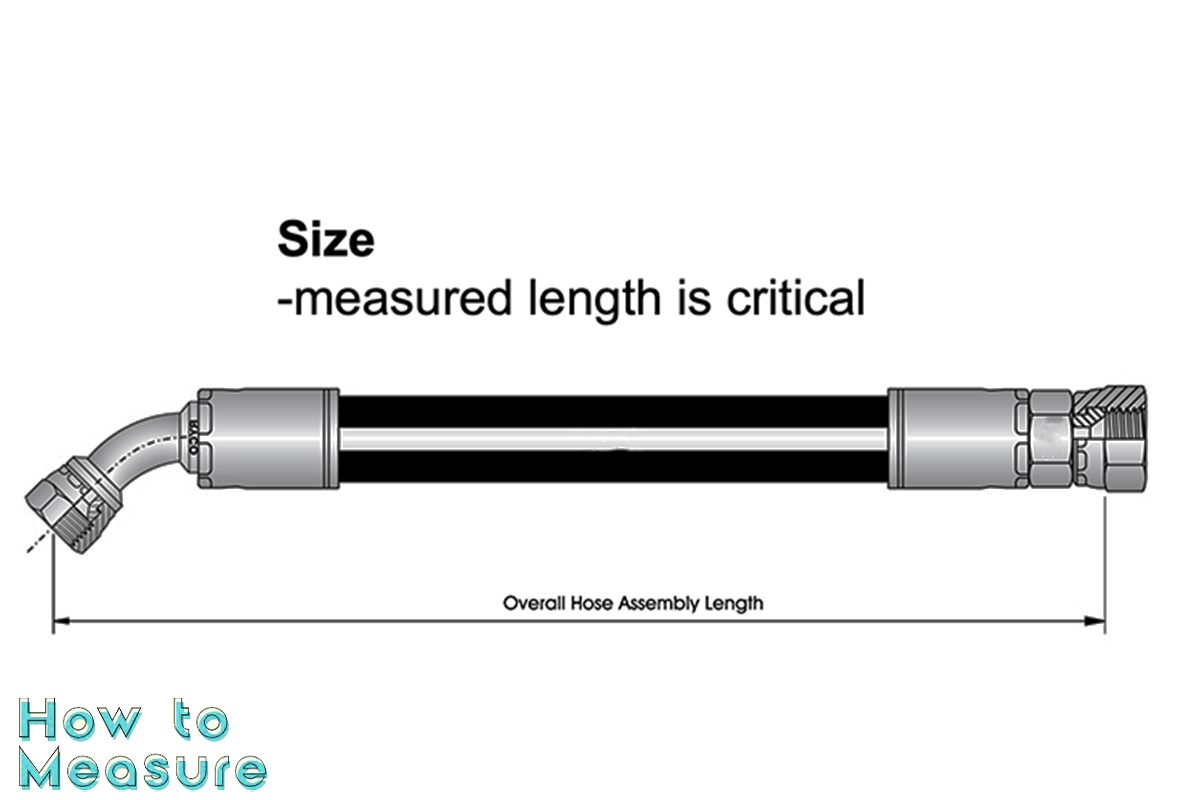

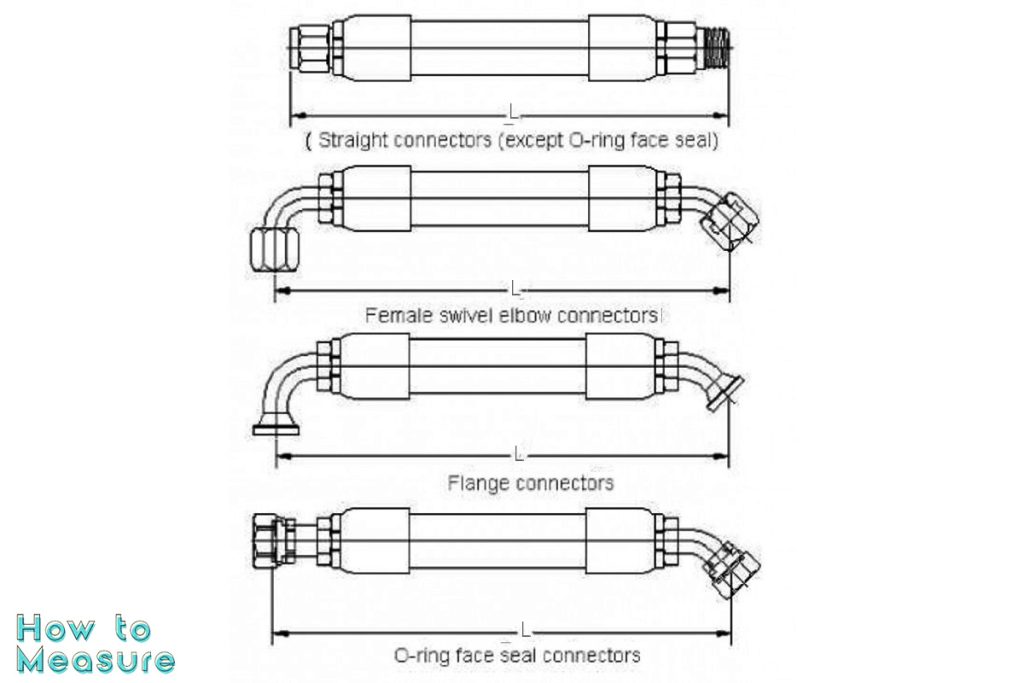

1. Length: Length is the most basic measurement for measuring hydraulic hose. This is done by measuring the length of the hose from end to end.

2. Diameter: The diameter of the hose is measured by using a caliper to measure the inside diameter of the hose.

3. Internal Pressure: Internal pressure is measured by using a pressure gauge to measure the pressure inside the hose.

4. Temperature: Temperature is measured using a thermometer to measure the temperature of the fluid inside the hose.

5. Wall Thickness: Wall thickness is measured using a micrometer to measure the thickness of the hose wall.

6. Bend Radius: Bend radius is measured using a ruler measure the radius of the bend in the hose.

7. Flow Rate: Flow rate is measured using a flow meter to measure flow rate through the hose.

8. Burst Pressure: Burst pressure is measured by using a pressure gauge to measure the pressure at which the hose will burst.

9. Resistance: Resistance is measured by using an ohmmeter to measure the resistance of the hose.

Understanding how to measure each of these parameters ensures that your hydraulic system functions properly and safely.

Measuring the Length of the Hydraulic Hose

Measuring the length of the hydraulic hose is essential in ensuring that the right size and type of hose is used for a particular application. The length of a hydraulic hose is determined by measuring from end to end, including any fittings or adapters. It is essential to measure the hose accurately to ensure that it is the correct length for the application.

To measure the length of a hydraulic hose, it is necessary to have a measuring tape or ruler. Start by measuring from the end of the hose, including any fittings or adapters, to the other end—measure in inches or centimeters, depending on the type of hose being measured. Make sure to measure the entire length of the hose, including any bends or curves. Once the length of the hose has been determined, it can be compared to the specifications for the application to ensure that it is the correct size.

It is important to note that the length of a hydraulic hose can be affected by temperature and pressure. If the hose is exposed to extreme temperatures or pressure, it may expand or contract, which can affect the length of the hose. Therefore, it is important to measure the length of the hose at the same temperature and pressure as the application. This will ensure that the correct length of the hose is used.

Measuring the Diameter of Hydraulic Hose

Measuring the Diameter of the Hydraulic Hose is an integral part of determining the system’s overall performance. The diameter of the hose affects the flow rate, pressure, and temperature of the system. To ensure the system is working correctly, measuring the diameter of the hose accurately is essential.

There are several methods for measuring the diameter of a hydraulic hose. The most common method is to use a caliper. A caliper is a tool that measures an object’s internal and external diameter. It is essential to use a caliper that is specifically designed to measure the diameter of the hydraulic hose.

Another method for measuring the diameter of a hydraulic hose is to use a micrometer. A micrometer is a tool that measures the diameter of an object by measuring the distance between two points. It is essential to use a micrometer specifically designed to measure a hydraulic hose’s diameter.

Measuring the diameter of the hydraulic hose using a ruler is also possible. This method is less accurate than using a caliper or micrometer, but it can provide a general idea of the diameter of the hose. To measure the diameter of the hose using a ruler, place the ruler along the length of the hose and measure the distance between the two points.

Measuring the diameter of the hydraulic hose is essential to ensuring the system is working correctly. Using the right tools for the job and taking accurate measurements are essential. By measuring the diameter of the hose, it is possible to ensure the system is working correctly and efficiently.

Measuring the Internal Pressure of Hydraulic Hose

Measuring the Internal Pressure of a Hydraulic Hose is essential in ensuring the safety and efficiency of hydraulic systems. Internal pressure is the amount of pressure that is exerted on the inside of the hose. It is essential to measure this pressure to ensure that the hose is not over-pressurized, which can lead to leaks or even hose failure.

You will need a pressure gauge to measure the internal pressure of a hydraulic hose. This gauge should be calibrated to the specific pressure range of the hose. Once the gauge is in place, you can attach the hose and start the system. As the system runs, the gauge will measure the internal pressure of the hose. If the pressure is too high, you can adjust the system accordingly to reduce the pressure.

It is important to note that the internal pressure of a hydraulic hose can vary depending on the type of system and the operating conditions. For example, a hose used in a high-pressure system will need to be able to withstand higher pressures than a hose used in a low-pressure system. Additionally, the temperature of the system can also affect the internal pressure of the hose.

When measuring the internal pressure of a hydraulic hose, it is essential to ensure that the gauge is calibrated correctly and that the system operates within the specified pressure range. This will help ensure that the hose is not over-pressurized, leading to leaks or even hose failure.

Measuring the Temperature of Hydraulic Hose

Measuring the temperature of the hydraulic hose is an important step in ensuring that the hose is functioning properly. Temperature can affect the hose’s performance, so it is important to measure it regularly. There are several methods for measuring the temperature of hydraulic hoses, including thermocouples, thermistors, and infrared thermometers.

Thermocouples are the most common method of measuring the temperature of a hydraulic hose. A thermocouple is a device consisting of two wires of different metals connected to each other. When the temperature of the hydraulic hose changes, the resistance of the two wires changes, allowing the temperature to be measured.

Thermistors are also used to measure the temperature of hydraulic hoses. A thermistor is a device that consists of a resistor that changes its resistance when the temperature of the hydraulic hose changes. The thermistor’s resistance is measured and used to calculate the temperature of the hose.

Infrared thermometers are also used to measure the temperature of hydraulic hoses. Infrared thermometers measure the infrared radiation emitted by the hose and use it to calculate the temperature.

No matter which method is used to measure the temperature of the hydraulic hose, it is essential to ensure that the readings are accurate. This can be done by using a calibration device to check the accuracy of the readings. This will ensure that the readings are accurate and that the hose functions appropriately.

Measuring the Wall Thickness of Hydraulic Hose

Measuring the wall thickness of the hydraulic hose is an essential step in determining the strength and durability of the hose. It is also important to know the wall thickness of the hose when selecting the correct size and type of hose for a particular application. There are several methods for measuring the wall thickness of a hydraulic hose, including using a caliper, a micrometer, or a wall thickness gauge.

Using a Caliper: A caliper is a tool used to measure the distance between two points. To measure the wall thickness of the hydraulic hose with a caliper, place the caliper on the outside of the hose and measure the distance between the inside and outside walls.

Using a Micrometer: A micrometer is a tool used to measure the thickness of an object. To measure the wall thickness of the hydraulic hose with a micrometer, place the micrometer on the outside of the hose and measure the distance between the inside and outside walls.

Using a Wall Thickness Gauge: A wall thickness gauge is a tool used to measure the thickness of a material. To measure the wall thickness of the hydraulic hose with a wall thickness gauge, place the gauge on the outside of the hose and measure the distance between the inside and outside walls.

It is important to note that when measuring the wall thickness of the hydraulic hose, the measurements should be taken at multiple points along the length of the hose to ensure accuracy. Additionally, using the correct type of tool for the job is essential, as using the wrong tool may result in inaccurate measurements.

Measuring the Bend Radius of Hydraulic Hose

Measuring the Bend Radius of a Hydraulic Hose is an essential step in ensuring the proper performance of a hydraulic system. The bend radius of a hose is the distance from the centerline of the hose to the point at which it bends. It is essential to measure the bend radius of a hose to ensure that it is not too tight or loose. If the bend radius is too tight, the hose may kink or become damaged, resulting in reduced performance and increased wear on the hose. If the bend radius is too loose, the hose may be prone to leaks or become disconnected from the system.

Measuring the bend radius of a hydraulic hose is relatively simple. First, measure the length of the hose from the centerline of the hose to the point at which it bends. This measurement should be taken in both directions to ensure accuracy. Once the length of the hose is determined, divide it by two to get the bend radius. This measurement should be taken with a ruler or caliper to ensure accuracy.

When measuring the bend radius of a hydraulic hose, it is essential to ensure that the hose is not under any tension. If the hose is under tension, the bend radius may be inaccurate. Additionally, it is essential to ensure that the hose is not kinked or damaged. The bend radius may need to be more accurate if the hose is kinked or damaged.

Measuring the bend radius of a hydraulic hose is an important step in ensuring the proper performance of a hydraulic system. By taking the time to measure the bend radius of a hose, you can ensure that the hose is not too tight or too loose and that it is not kinked or damaged in any way. This will help ensure that the hose performs as expected and does not become disconnected from the system.

Measuring the Flow Rate of Hydraulic Hose

Measuring the flow rate of a hydraulic hose is an integral part of determining the performance of the system. The flow rate of a hydraulic hose is the amount of fluid that passes through it in a given amount of time. It is essential to measure the flow rate of a hydraulic hose in order to ensure that the system is operating efficiently and safely.

There are several methods for measuring the flow rate of a hydraulic hose. The most common method is to use a flow meter. A flow meter is a device that measures the rate of flow of a fluid through a pipe or hose. It can be used to measure the flow rate of a hydraulic hose by attaching it to the end of the hose and measuring the amount of fluid that passes through it in a given amount of time.

Another method for measuring the flow rate of a hydraulic hose is to use a pressure gauge. A pressure gauge measures the pressure of the fluid in the hose. By measuring the pressure of the fluid, it is possible to calculate the flow rate of the hose.

Finally, the flow rate of a hydraulic hose can also be measured using a flow chart. A flow chart is a diagram that shows the relationship between the fluid’s pressure and the hose’s flow rate. Using a flow chart makes it possible to determine the flow rate of a hydraulic hose without the need for a flow meter or pressure gauge.

Measuring the flow rate of a hydraulic hose is an essential part of ensuring that the system is operating safely and efficiently. By using a flow meter, pressure gauge, or flow chart, it is possible to accurately measure the flow rate of a hydraulic hose and ensure that the system is functioning correctly.

Measuring the Burst Pressure of Hydraulic Hose

Measuring the Burst Pressure of a Hydraulic Hose is an essential step in ensuring the safety and efficiency of any hydraulic system. The burst pressure of a hydraulic hose is the maximum pressure it can withstand before it fails. Knowing the burst pressure of a hose is essential for determining the right size and type of hose for a particular application.

There are several methods for measuring the burst pressure of a hydraulic hose. The most common method is to use a hydrostatic test pump to pressurize the hose to the desired pressure. The pressure is then monitored with a gauge to determine the burst pressure. Other methods include using a pressure transducer or a pressure sensor to measure the pressure.

It is important to note that the burst pressure of a hydraulic hose can vary depending on the type of hose, the size of the hose, and the temperature of the fluid. It is also important to note that the burst pressure of a hose can be affected by the age of the hose, the type of material used in the hose, and the pressure rating of the hose.

When measuring the burst pressure of a hydraulic hose, it is essential to use the correct equipment and follow the manufacturer’s instructions. It is also essential to use the correct type of hose for the application and ensure that it is properly maintained and inspected.

By measuring the burst pressure of a hydraulic hose, it is possible to ensure that the hose is suitable for the application and that it is safe to use. This will help ensure that the hydraulic system is operating at its optimal efficiency and is safe for use.

Measuring the Resistance of Hydraulic Hose

Measuring the resistance of a hydraulic hose is essential in ensuring the safety and efficiency of any hydraulic system. Resistance measures the energy required to move a given volume of fluid through a given hose length. The resistance of a hydraulic hose is typically measured in ohms and is determined by the size, length, and type of hose being used.

When measuring the resistance of a hydraulic hose, it is essential to consider the following factors:

- The size of the hose: The size of the hose will affect its resistance of the hose. Larger hoses will typically have higher resistance than smaller hoses.

- The length of the hose: The longer the hose, the higher the resistance.

- The type of hose: Different hoses will have different resistance levels. For example, rubber hoses typically have higher resistance than metal hoses.

- The temperature of the fluid: Higher temperatures will increase the resistance of the hose.

- The viscosity of the fluid: The higher the viscosity of the fluid, the higher the resistance of the hose.

Measuring the resistance of a hydraulic hose is essential in ensuring the safety and efficiency of any hydraulic system. By taking into account the size, length, type, temperature, and viscosity of the fluid, you can accurately measure the resistance of the hose and ensure that it is functioning correctly.

For read more articles, vitis How to Measure website